SK1265-AT6 eLift

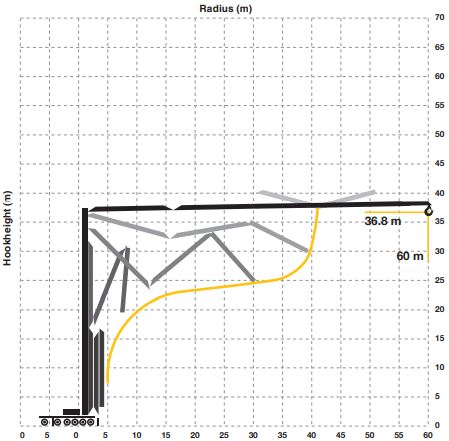

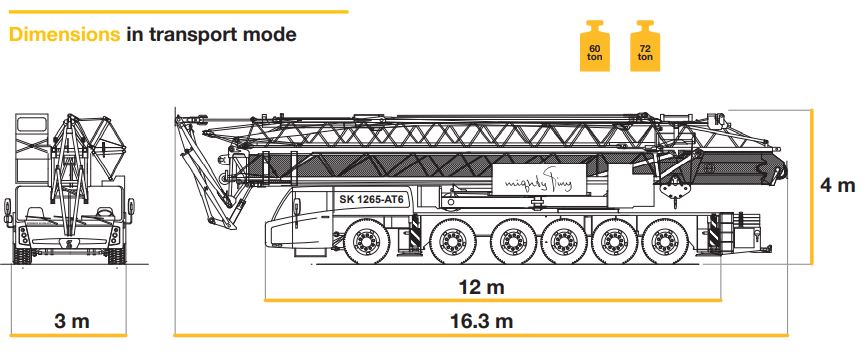

The six-axle Spierings SK1265-AT6 eLift is the largest mobile tower crane in the world and can operate 100% emission free. The powerful engine, high-performance pneumatic brake system and excellent overview increase safety on construction sites and public roads. The SK1265-AT6 eLift is the first Spierings crane with a fifth extendible jib section, which, combined with the four other jib sections, delivers an unrivalled radius of 60 meters.

Specifications

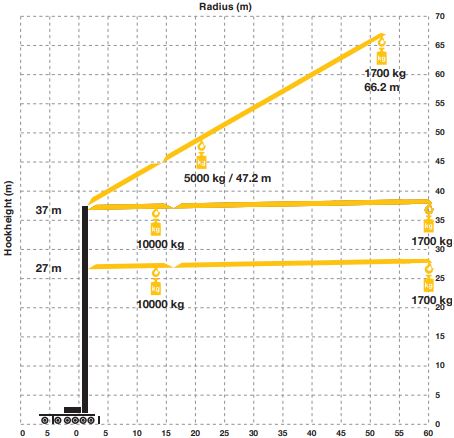

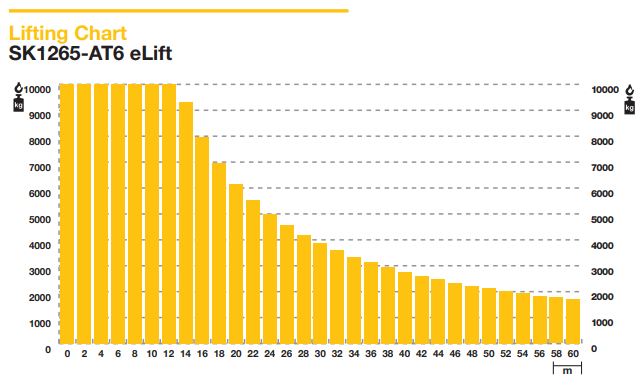

- Maximum load10,000 kg (up to 13.2 m)

- Tip load1700 kg

- Maximum radius60 m

- Lifting height35 m

- Tower height37.2 m

- Maximum lifting height64.2 m (30° luffed jib)

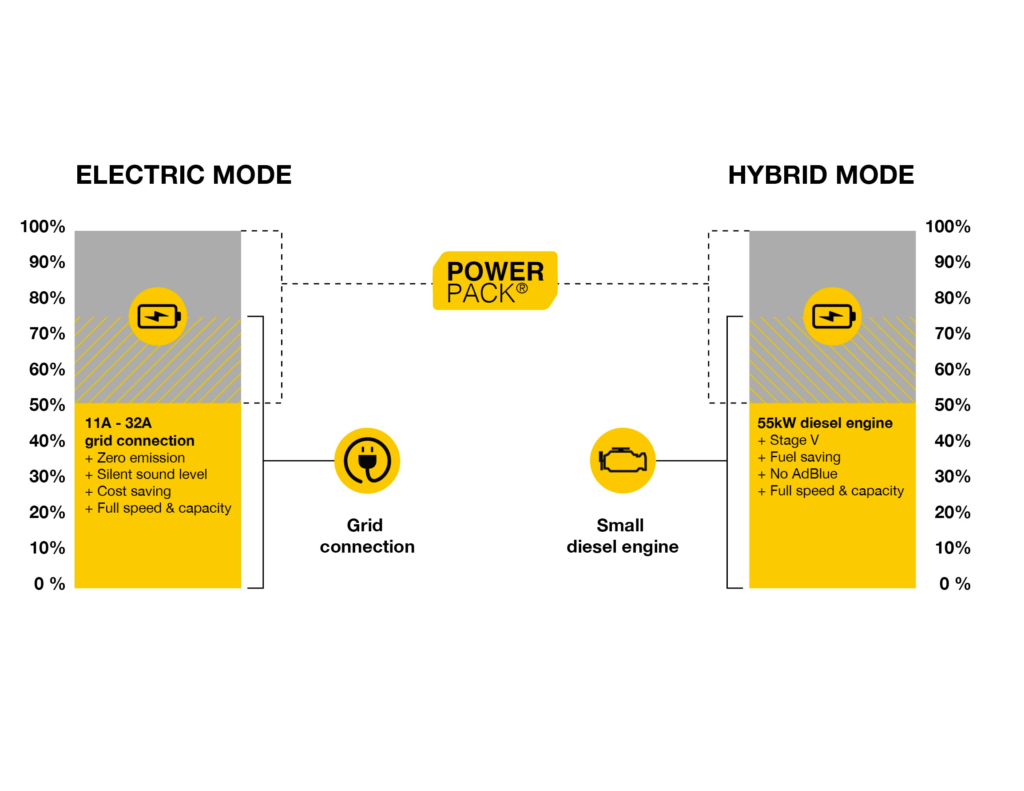

Full electric & hybrid mode

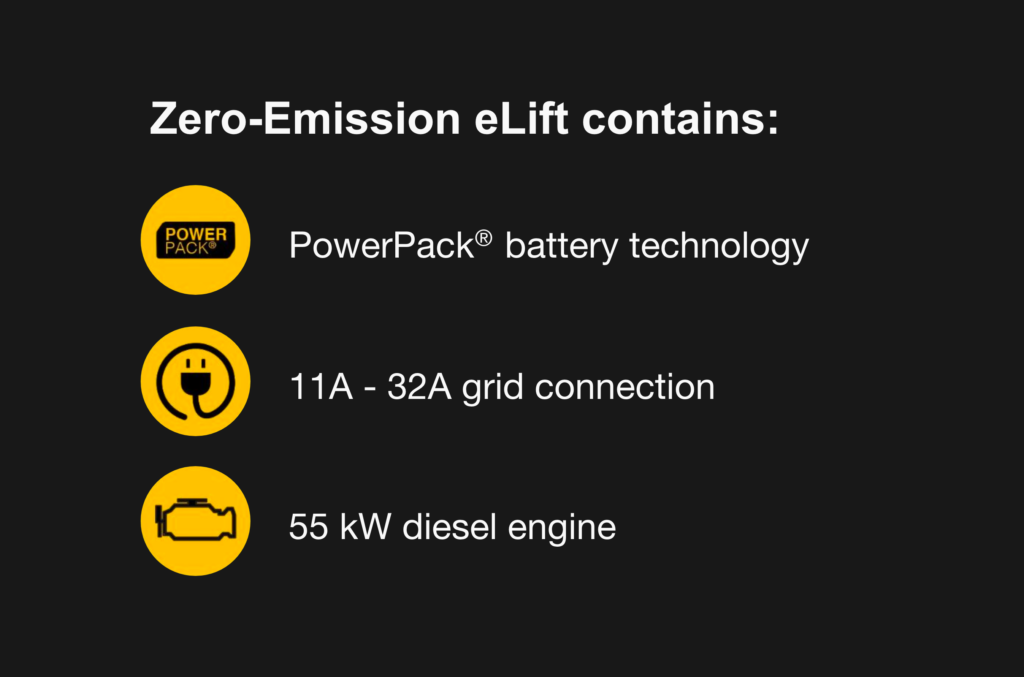

The Zero-Emission eLift system has two operating modes; electrical mode and hybrid mode. Both modes have an efficient first line energy source, which can be chosen for the grid connection or diesel engine. The PowerPack® battery technology absorps the peaks in energy usage and will be charged when energy is unused. By using the electric mode you operate the crane 100% emission free on a silent sound level without any limitations in usage.

To operate the crane in electric mode it needs to be connected to a 32A grid connection that’s quite often available at most job sites. The system is using between 11A and 25A which can be pre-set at the display, so there is still energy left for other purposes.

A small 55kW 3-cylinder diesel engine with the newest Stage V emission certification is the main energy source during hybrid mode. The unused energy of the diesel engine is used to recharge the battery of the PowerPack®, so it can be used for peak absorption.

The benefits

One job, one man

100% Electric hoisting

Setup in 11 minutes

Steel pads

Hydraulic motions

LED lighting in the jib

Very spacious cabin

16a or 32a grid connection

Operate the SK597-AT4 eLift or SK1265-AT6 eLift full electric by a grid connection between 11A and 32A which can be pre-set at the display, so there still can be energy left for other equipment on site.

PowerPack® battery technology

The PowerPack® battery technology absorbs the peaks in energy usage and will be charged when energy requirement for the crane is low.

Free of noise & emission

Operate the eLift crane completely free of noise while operating in ‘electric mode’. Especially during city jobs and night jobs it’s a great advantage to work noise- and emission free.